Expanding Electric Vehicle Stock Generating Global Demand for Oxygen-Free Copper

The Government of France has set up a target of increasing plug-in electric vehicle (PHEV) (passenger vehicles) and battery electric vehicle (BEV) (passenger vehicles) stock to 1.8 million and 3 million, respectively, by 2028. Likewise, Indonesia aims to expand the electric vehicle (EV) stock (passenger vehicles) to 2 million units by 2030. Similarly, the New Zealand government aspires to introduce 64,000 EVs (passenger cars) by 2025. The increasing number of EVs, on account of the growing need to reduce vehicular emissions, will, therefore, augment the need for oxygen-free copper products worldwide.

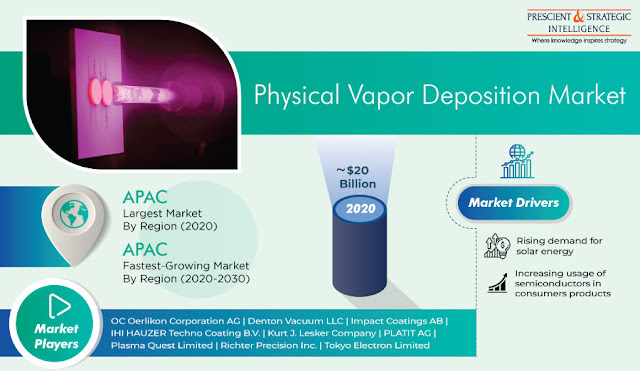

Moreover, the expanding electrical and electronics industry will also steer the oxygen-free copper market growth during the forecast period (2021–2030). According to P&S Intelligence, the market generated nearly ~$20.0 billion revenue in 2020. The growth of the electrical and electronics industry can be ascribed to the rising demand for consumer electronics, especially in developing countries, due to the mounting disposable income of people. For instance, the gross national disposable income of India increased from INR 1,73,15,933 crore during 2017–2018 to INR 1,92,37,943 crore during 2018–2019.

In the coming years, the electrical and electronics industry will utilize a significant volume of oxygen-free copper wires, busbars, strips, and rods to meet the booming demand for superconductors and semiconductors. Additionally, the surging power demand, on account of the growing global population, will also create a huge requirement for various types of oxygen-free copper products. In recent years, oxygen-free copper wires have been consumed in the highest quantity, due to their large-scale usage in vacuum seals, vacuum capacitors, vacuum interrupters, and microwave tubes.

The grade segment of the oxygen-free copper market is bifurcated into oxygen-free and oxygen-free electronic. Under this segment, the oxygen-free bifurcation held the larger market share in 2020, and it is projected to maintain its lead in the forecast years as well. The dominance of this category can be attributed to the increasing use of oxygen-free copper in electromagnets, magnometers, and other semiconductors and magnifying demand for EVs, owing to the rising government support toward the EV industry.

In recent years, oxygen-free copper providing companies have actively focused on acquisitions to offer this material to a greater number of customers. For instance, in February 2021, Mitsubishi Materials Corporation acquired a minority share in Mantoverde copper mine of Chile for $275 million. With this acquisition, the company will have a constant supply of high-quality copper concentrates with minimal impurities and a sustainable raw material portfolio of e-scrap and clean copper concentrates.

Therefore, the surging adoption of EVs and prospering electrical and electronics industry will facilitate the usage of oxygen-free copper all over the world in the upcoming years.